Decolor Without Waste Award

The “Neochromato Process”

, a polyester textile decoloring technology that enables the reuse of garments by changing their colors and patterns.

Masaaki Sugimoto / Mitsuo Matsuda

Description

Detailed explanation of the submitted project or idea.

※ Textile Exchange Preferred Fiber & Materials Market Report 2020

(en)

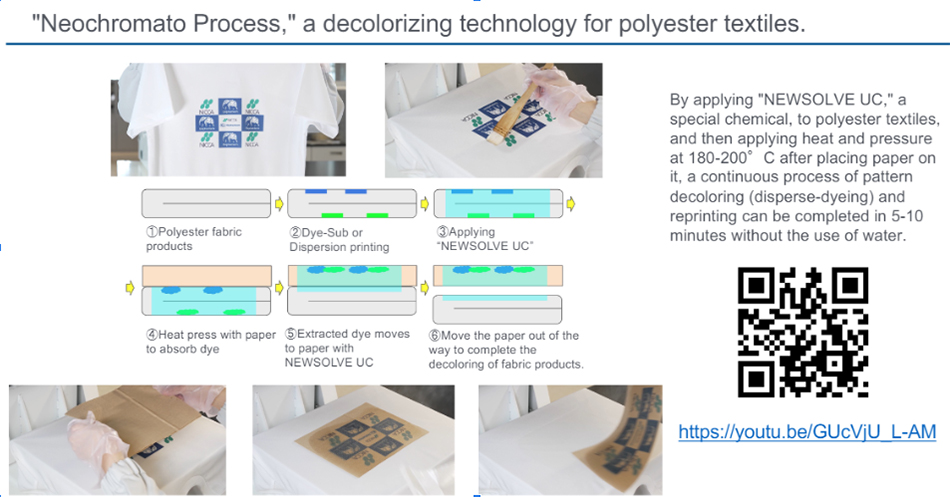

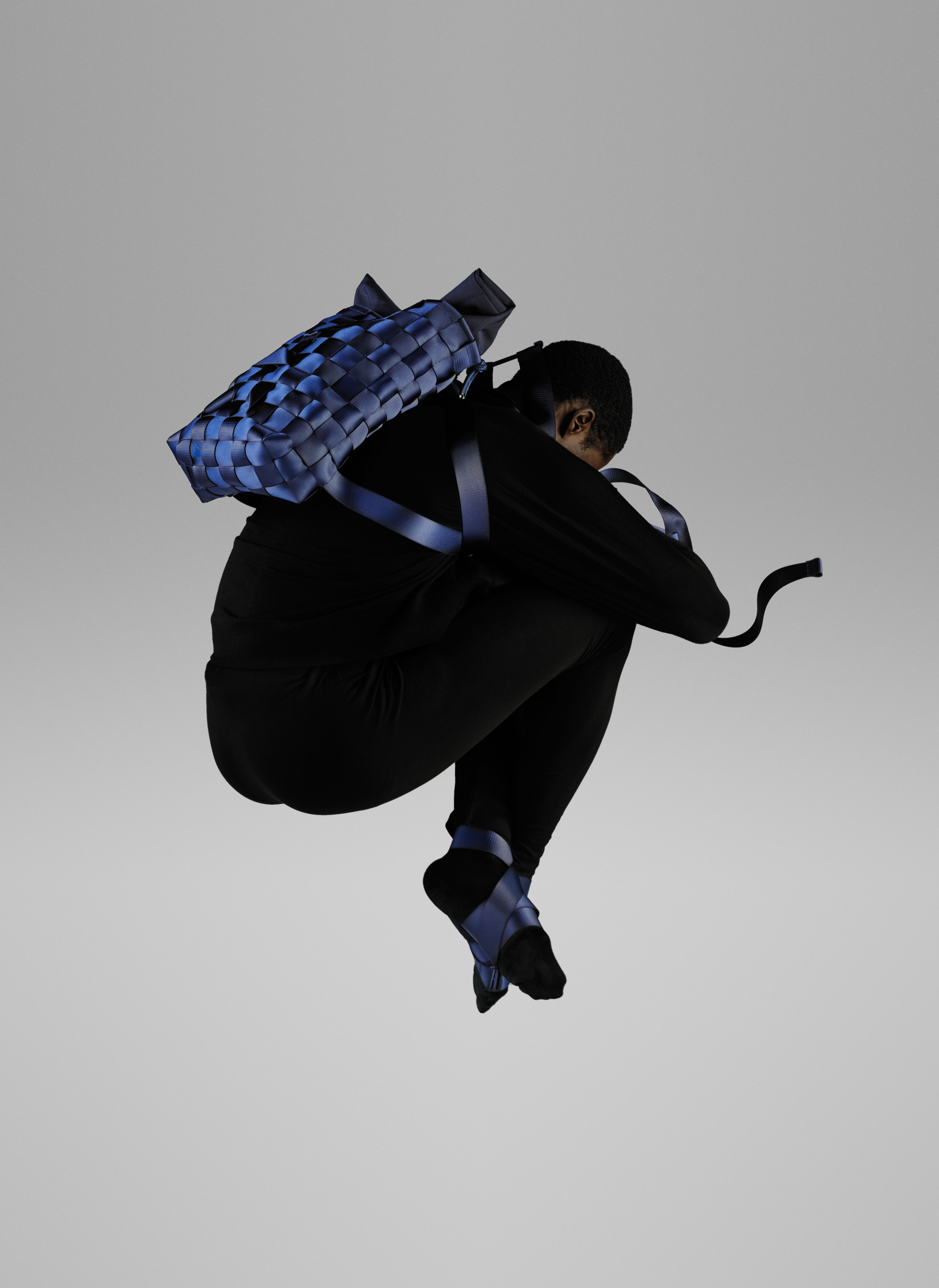

Polyester Textile decoloring Technology “Neochromato Process.”

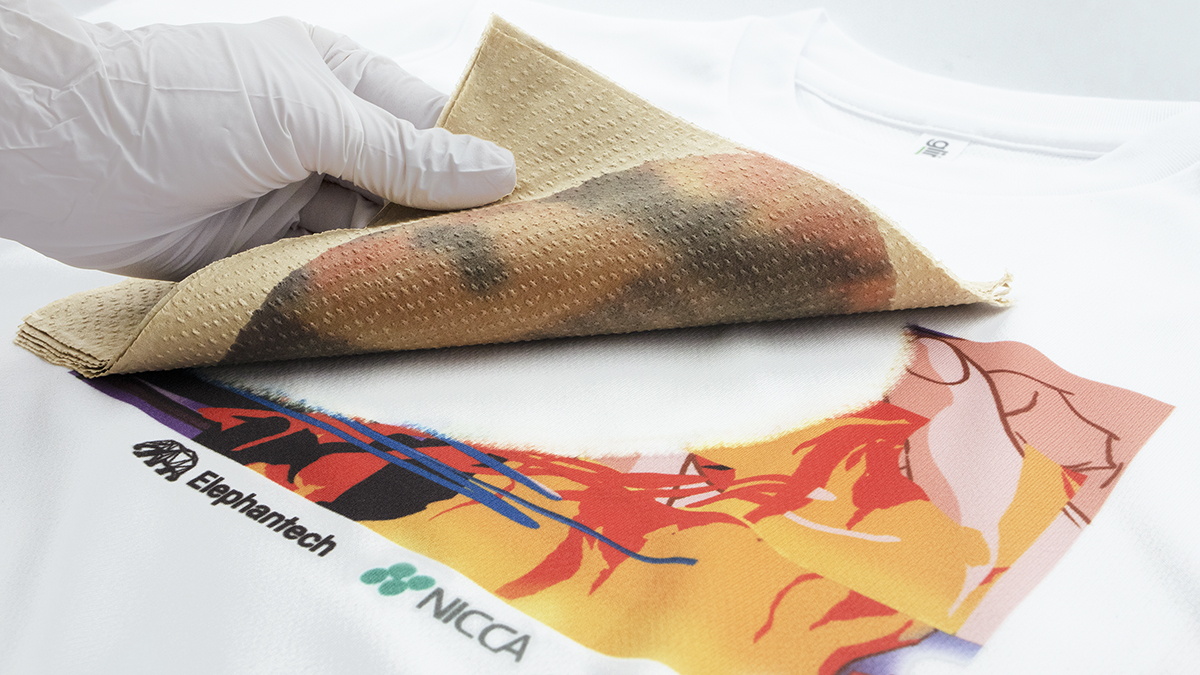

Elephantech has jointly developed with NICCA Chemical the “Neochromato Process,” a polyester textile decoloring technology that enables the reuse of clothing fabrics by changing their colors and patterns.

With the growing momentum to reduce greenhouse gas emissions, more consideration is being given to environmental impact. Japanese Ministry of the Environment says, “the fashion industry is considered an industry with a huge environmental impact. Because due to the amount of energy used in manufacturing and short life cycles. That is an international issue that requires improvement”. Sustainable initiatives that shift away from mass production, consumption, and disposal are beginning to attract attention. Among these, polyester is the most widely used material, accounting for 52%* of all fibers produced in 2019. The percentage of recycled polyester has risen to 14% of that total. Still, most of that is produced from materials in the uncolored, non-textile sector, such as PET bottles. One of the significant obstacles to textile-to-textile recycling is the difficulty of decoloring polyester fibers.

The Neochromato process is a new reuse technology that can change the color and pattern of polyester clothing as many times as needed. Creating new usages for recycling apparel and other sewn products is important before they are crushed or dissolved in chemicals. This reuse technology can extend product life and reduce environmental impact.

The “Neochromato process,” which contributes greatly to reducing environmental impact, has the following features.

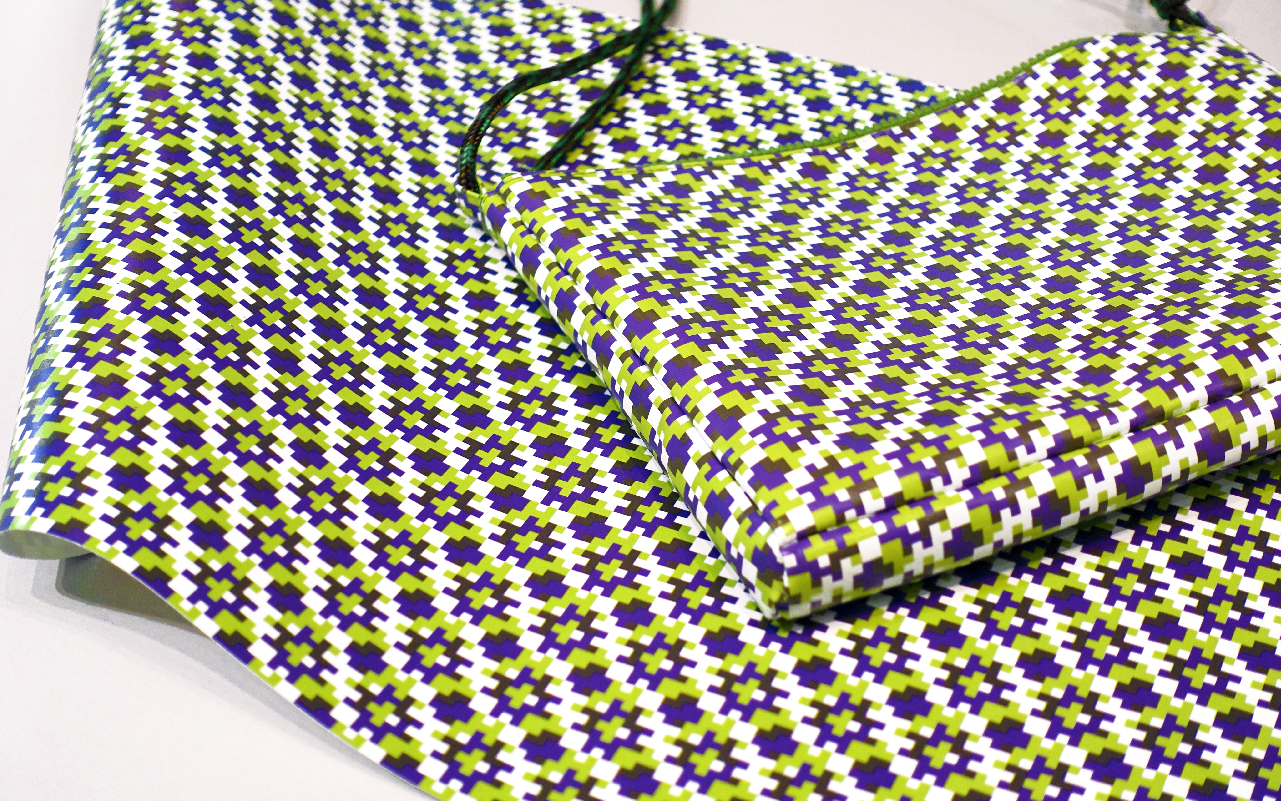

・Decoloring is possible for polyester fabrics dyed with disperse dyes (dyeing, textile printing, sublimation transfer, etc., are all possible).

・After decoloring by a waterless process (including solvent removal), printing and dyeing are possible, and you can change the color pattern as often as possible.

・The special solvent is made from the waste generated in another process.

・Solvent consumption is extremely low compared to competing methods (about the same as the weight to be treated) and can be collected and reused.

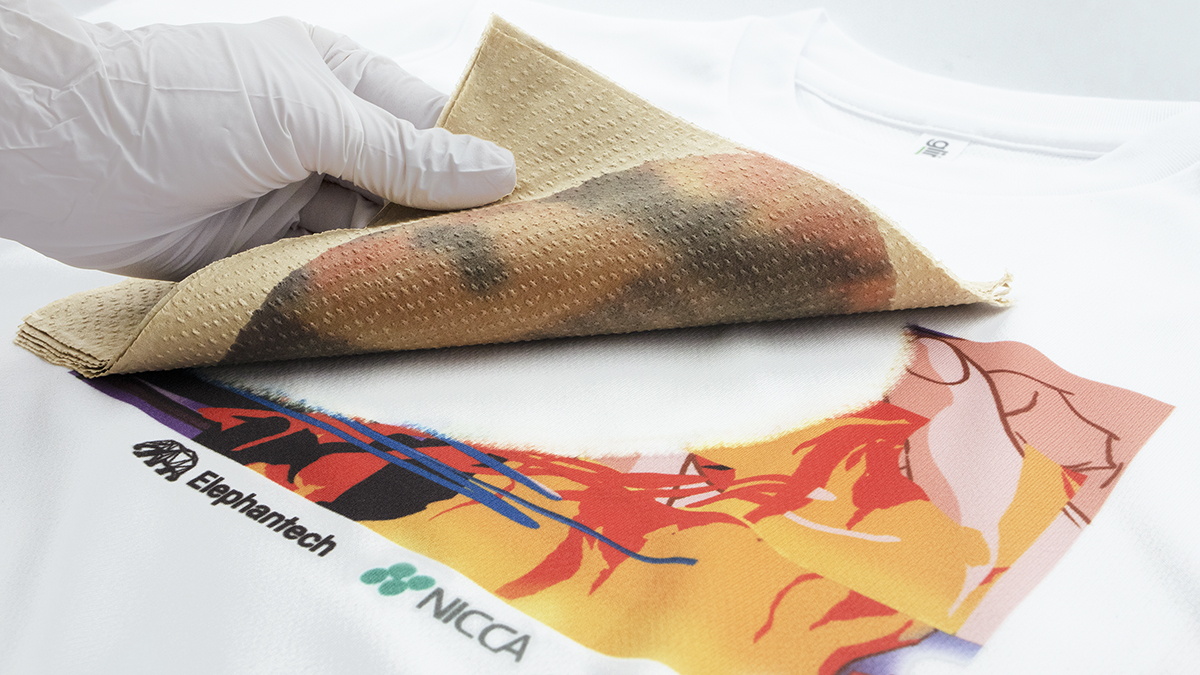

The process achieves decoloring without using any water by extracting the disperse dye that dyes the polyester fabric and absorbing it with paper simultaneously. The absorbent paper that absorbs the disperse dye and solvent can be disposed of as burnable waste. It can minimize water use and water pollution from wastewater, making this a sustainable technology contributes to biodiversity.

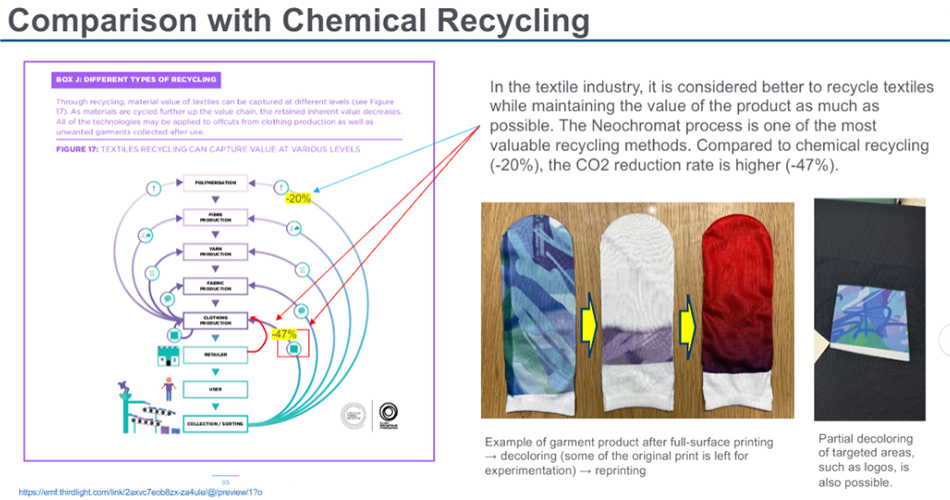

In addition, the ability to recycle clothes in their actual form, without going through the process of making cloth from yarn and garment products, helps to keep the product’s value for a more extended period and increases CO2 emissions reduction.

* Textile Exchange Preferred Fiber & Materials Market Report 2020

Link

Comments from Judges

Mitchell van Dooijeweerd

Sustainability Manager of DGTL Festival / Revolution Foundation

Decolor Without Waste Award

Great innovation! I am looking for this kind of innovations already for years. Clothing waste and fast fashion issue is huge, this can help the industry a lot.

Big events are using printed clothes for crew, with a logo or name on the t-shirt. Nowadays we couldn’t reuse them for the next years, when we would change the logo’s. In this case we can buy shirts and use it for multiple events during the year. If this is something that can be done quick and relatively cheap, this will be a great innovation for the transition towards a more sustainable fashion industry.

See All Winners